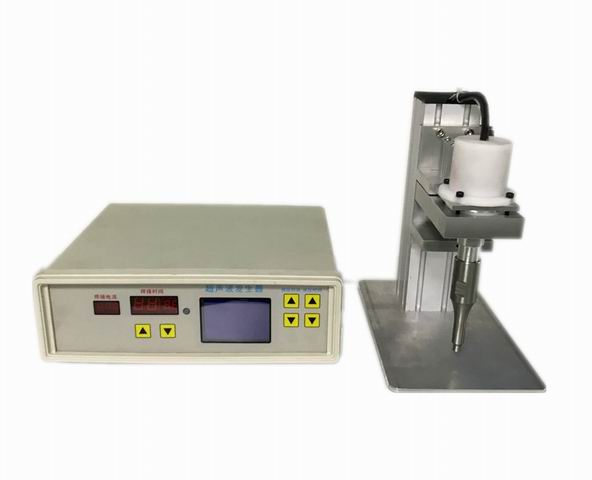

LTC-U2000 Ultrasonic Spot Welding Machine for Plastic and Metal

Product Description

Application of LTC-U2000 Ultrasonic

Face Mask Ear Loop Spot Welder:

The ultrasonic spot welder LTC-U2000 uses ultrasonic wave to fuse the

ear loop on both sides of the mask body to complete the face masks. Only one

operator needs to place the mask piece on the welding head of the ultrasonic

generator, and then put the ear loop on the mask piece. Push the foot pedal

makes the cylinder move downward to sew the strap and the mask piece.

This ultrasonic spot welding machine is easy to operate, economical and

practical, and can quickly recover the investment.

Main technical parameters:

|

No. |

Parameter Item |

|

|

1 |

Maximum output power |

1000W |

|

2 |

Ultrasonic frequency |

28KHZ |

|

3 |

Input voltage |

220V50HZ |

|

4 |

Welding time |

0.1S adjustment |

|

5 |

Preloading time |

0.01S adjustment |

|

6 |

Pressure holding time |

0.01S adjustment |

Functional

Features:

1. Microcomputer control, digital automatic frequency

tracking, 28K ultrasonic frequency, with liquid crystal display, easy to

operate.

2. Flexible setting of welding parameters and

arbitrary adjustment of welding speed can greatly improve welding efficiency

and quality.

3. Express delivery start, high-speed welding,

automatic rise of the head after welding.

4. The mould adopts round head, the welding surface is

beautiful and the welding quality is guaranteed.

5. It can quickly weld flat, N95 and other mask ear

loops.

6. The pressing time and back-up time of the welding

head can be set. There is no need to manually control the back-up time. The

operation is more labor-saving and humanized.

Principle of Ultrasonic Welding Machine:

When the ultrasonic wave acts on the contact of thermoplastic materials, it will generate tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration reaches a certain amplitude, which will generate local high temperature. Because of the poor thermal conductivity of the plastic, the temperature can not be distributed in time for a while, and it will gather in the welding area, until the contact surfaces of the two plastics melt rapidly. When a certain amount of pressure is applied, it will be integrated. When the ultrasonic stop, let the pressure last for several milliseconds, make it solidify and form a solid molecular chain, achieve the purpose of welding, and the strength is close to the strength of raw materials.

Deutsche

Deutsche Español

Español français

français italiano

italiano português

português 日本語

日本語 한국어

한국어 العربية

العربية русский

русский bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt