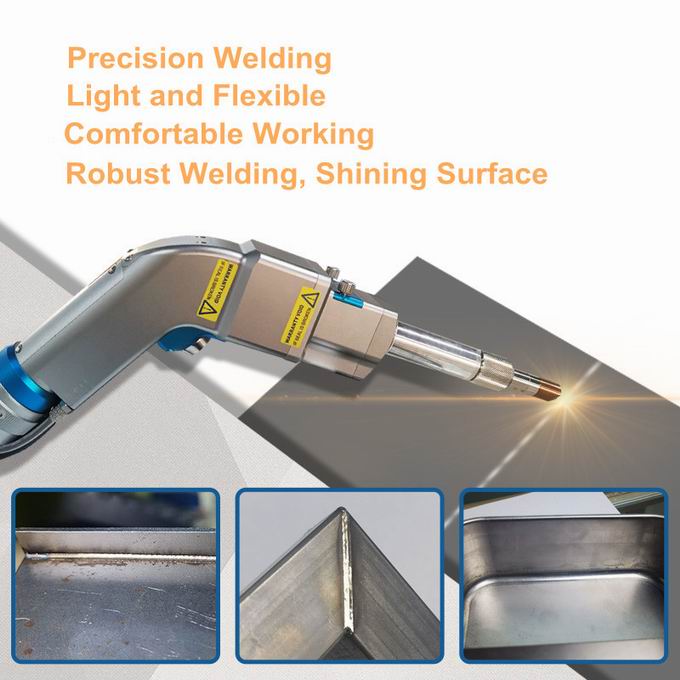

Lk CE Certificated Wobble Head Handheld Fiber Laser Welding Machine for Stainless Steel Iron Aluminum Copper Brass

Product Description

Product Description

Basic Info.

Model NO.

LK-H1000

Warranty

1 Year

Application

Biomedicine, Electronic Industry, Automotive Industry, Manufacturing Industry

Technical Class

Control

Power Density

Deep Fusion Welding

Laser Classification

Optical Fiber Laser

Type

Laser Spot Welder

Trademark

LK

Transport Package

Export Wooden Box Packing

Specification

800X680X1500mm

Origin

China

HS Code

8515800090

Product Description

Product Description

LK-1000 Laser Handheld Welding Machine has the advantages of fast welding efficiency, compact machine and convenient operation, which greatly improves the work efficiency. Compared with the current optical fiber transmission welding, it has higher electro-optic conversion efficiency, better beam quality, less maintenance cost and higher welding speed.

Scope of Application

The system is applicable to the welding of metals (including rare metals), electroplating materials, it is more suitable for processing some products requiring fine and high precision.

1.Applicable to hardware tools, auto parts, sanitary ware, medical instruments, communication equipment, bearings, sanitary ware, hardware products, tool accessories, precision instruments, knives, locks, cookware, stainless steel products and other industries.

2.Applicable materials include: common metals and alloys (all metals such as iron, copper, aluminum, magnesium and zinc), rare metals and alloys (gold, silver and titanium), metal oxides (all kinds of metal oxides), special surface treatment (phosphating, aluminum anodizing, electroplating surface).