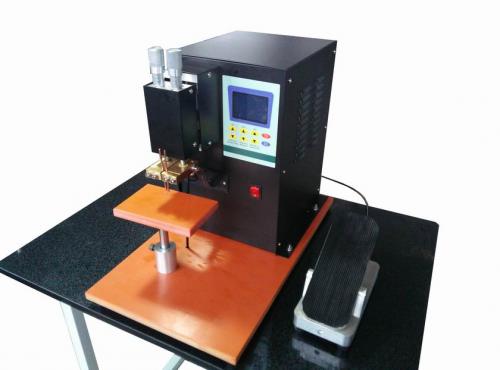

Battery Spot Welder LTC-A5000. Air driving

Product Description

Battery Spot Welder LTC-A5000

Watch the welding videos, please click the YOUTUBE URL:

https://m.youtube.com/watch?v=sIV8SJRmnio

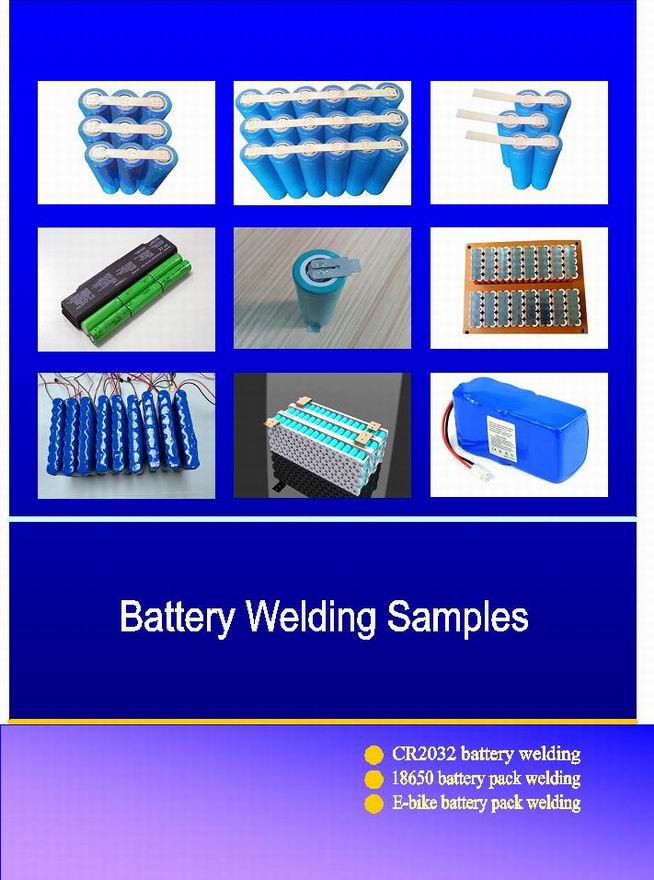

LTC-A5000 is a AC double pulse micro battery pack spot welding machine, it is widely use in welding 0.1—0.3mm thickness battery pure nickel strips. With air driving, easy operating and economic. Battery rebuild and assemble factories and workshops use this battery spot welder to weld E-bike battery pack, Power tool battery pack, Drill battery, Self balancing scooters battery pack, Segway battery pack, Battery tabs, Battery nickel strips, 18650, 26650, CR2032 battery cells, lithium battery, 3A battery, D-cell battery, Ni-MH battery, Ni-Cd battery, battery welding pure nickel strips and tabs, battery accessories.etc.

Instruction

LTC series battery assembly welding power source adopts Japan the most advanced welding technology, is the present domestic advanced level of high performance precision resistance welding machine, designed for the production of high-end mobile phone batteries, power batteries, digital batteries, nickel metal hydride, nickel cadmium battery, such as needed to design, also can welding parts, LED lights, electronic components, feet, capacitance, etc.

The precision resistance welding power source is the IGBT inverter technology, microcomputer control technology and modern power electronic technology development of a new type of power supply. Time control millisecond precision, control response and control precision is greatly increased; Significantly improve welding technology; Advanced technology and equipment has advantages of small, energy efficient and a series of; Microcontroller (MCU) and the using of electronic technology makes the equipment with outstanding features of modern equipment, including digital control, monitoring, fault diagnosis and protection, data transmission, etc., equipment is fully functional, flexible, convenient, adaptation of wide.

2.2 The main technical characteristics:

Double pulse welding:

Double pulse welding, the first pulse is used to clear the workpiece surface coating and oxide, and make the contact place in welding electrode produce slight deformation, improve the effective contact area, the second pulse is used to ontology metal welding, can effectively promote the quality of welding and reducing welding spatter.

Control mode:

CPU control, precision adjustable pulse energy (0-999 ‰), the number of pulse frequency can be adjusted (0 to 8), preloading time adjustable (0 to 8), locking function parameters.

Many fault protection:

Welder power circuit and control circuit, is equipped with two sets of different kinds of protection circuit, in order to prevent the equipment overheating, external pressure and power fluctuations of welder interference; In order to protect the damage to the welder in harsh environment. For some common fault prompt functions, butt welding machine overheating and damage, will automatically alarm, and at the same time to cut off the power supply.

Precision welding head design.

It use air cylinder to make the two combined with spring buffer, which is can relative to adjust needle welding in the welding pressure, due to the effect of the buffer of the spring, the cylinder does not directly effect on the solder joint, thus effectively protect welding plane.

Inside of machine head adopts photoelectric pressure switch, and only in two welding needle discharge welding pressure to achieve the set pressure, protect the reliability of the welding, and double needle pressure can be adjusted.

Unique structure:

l stepless lifting table, the adjustment convenient location precision.

l unibody design, pneumatic operation, easy operating easily.

The main technical parameters

|

Number |

Project |

Parameters |

|

1 |

Power |

15KVA |

|

2 |

Secondary side welding current |

3000A |

|

3 |

Secondary floating voltage |

5.5V |

|

4 |

Weling control mode |

single/double pulse |

|

5 |

Maximum working pressure |

6KG |

|

6 |

Prewelding pulse energy |

0-100.0% |

|

7 |

Welding pulse energy |

0-100.0% |

|

8 |

Program-Changed welding |

Yes |

|

9 |

Welding mode |

Basic welding/Link welding |

|

10 |

Input voltage |

220V |

|

11 |

Input frequency |

50HZ |

|

12 |

Max working air pressure |

|

|

13 |

Welding control |

Air driving, foot fire switch welding |

|

14 |

Weight |

30KG |

|

16 |

Overall dimensions |

400L*220W*360mmH |

|

18 |

Welding electrodes diameter |

Φ3 or Φ6 mm |

|

19 |

Nickel strip welding thickness |

0.08mm-0.4mm |

Deutsche

Deutsche Español

Español français

français italiano

italiano português

português 日本語

日本語 한국어

한국어 العربية

العربية русский

русский bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt